Pure Steam is like the unsung hero in the healthcare tale. Not only does it help to eliminate germs, but it also helps to treat respiratory ailments and chronic wounds. In addition, the application of pure steam in healthcare to maintain a sterile environment proves to be cost-effective and safe compared to chemical methods.

In this blog, we’re spilling the beans on how this quiet superhero, pure Steam, ensures hospitals and labs stay clean and safe for everyone. Keep reading to learn about the applications and benefits of using pure steam in healthcare.

8 Applications of Pure Steam in Healthcare

Sterility is a non-negotiable requirement in healthcare facilities, primarily where medical procedures are conducted and pharmaceuticals are manufactured. Contaminants like bacteria, viruses, and fungi pose severe threats to patient health and can compromise the efficacy of medical treatments. Maintaining sterility is not just a regulatory requirement. Still, it is a fundamental aspect of patient care and safety.

Here are 8 ways Pure steam is widely utilised in healthcare environments for several critical purposes:

1. Sterilisation to Control Infection:

Steam has proven to be a powerful tool for sterilisation in healthcare settings for ages. Pure Steam is the primary choice for autoclaves and sterilisers to disinfect medical instruments, surgical equipment, and other healthcare apparatus. Its high temperature and purity levels make it an effective agent for eliminating microorganisms, spores, and other contaminants.

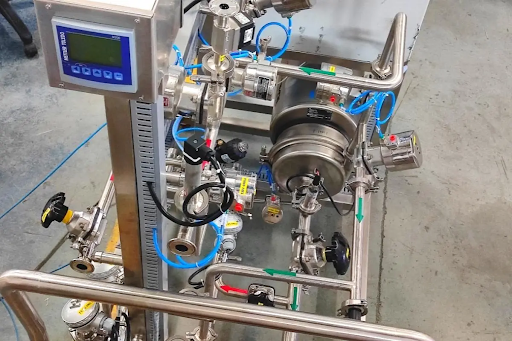

TSA’s Pure Steam Generator stands out as a unique purification system featuring a sophisticated mechanical design in SS 316L. Aligned with TSA technology standards, it guarantees enhanced performance and energy efficiency. It works in compliance with USFDA 21 CFR part 11 and GAMP 5 and has optional features like double tube sheeting, pre-heaters, and exchangers.

For more information, check this Pure Steam Generator here.

2. Pharmaceutical Manufacturing:

Precision and sterility are paramount in pharmaceutical manufacturing. Therefore, pure steam is employed during the clean-in-place (CIP) and sterilize-in-place (SIP) practices to meet stringent hygiene standards effectively.

3. Humidification in Controlled Environments:

Controlled environments like operating rooms and laboratories require precise humidity. Pure steam is used for humidification in these spaces to prevent the growth and spread of contaminants while maintaining optimal conditions for equipment and human occupants.

4. In-Surgical Operations:

Procedures such as laparoscopic surgery, known for their minimally invasive approach, utilise abdominal insufflation with pure steam. This technique ensures a clear visual field for surgeons, enabling them to conduct surgeries with enhanced precision and reduced patient trauma. The result is expedited recovery times for individuals undergoing these advanced surgical procedures.

5. Wound Recovery:

Steam or moist heat therapy is applied to recover chronic wounds. When controlled steam is used to treat wounds, it improves blood circulation, thus promoting tissue regeneration and speeding up healing time.

6. To treat Respiratory Conditions:

Inhaling steam is a common home remedy for respiratory issues and has clinical applications. Patients with bronchitis, asthma, and sinusitis rely on steam inhalation therapy to loosen mucus and allow patients to breathe easily.

7. In Saunas and Rehab Centers:

Sauna therapy subjects the body to elevated steam and heat levels, fostering improved cardiovascular health, heightened circulation, and accelerated muscle recovery. Specific rehabilitation centres integrate steam saunas into their treatment protocols to augment patients’ overall well-being.

8. Alleviate Pain:

Steam offers a comforting touch to alleviate pain and muscle tension through different methods. Embracing steam baths, relaxing in steam rooms, or applying warm steam packs has proven effective in easing muscle tension, reducing stiffness, and providing soothing relief. Pure steam is precious for individuals dealing with chronic pain conditions, offering a gentle and nurturing approach to enhance their well-being.

8 Benefits of Pure Steam in Healthcare

Pure steam is not just a wallet-friendly choice, but your go-to solution for creating and sustaining a clean and germ-free healthcare environment. In this blog section, we explore the added perks like reliability, consistency, efficiency, and eco-friendly features. Let’s unravel the full spectrum of benefits!

1. Reliability and Consistency:

Pure steam generators are designed to provide a consistent and reliable source of high-purity steam. The consistency of a pure steam generator ensures the effectiveness of sterilisation processes and maintains a sterile environment.

2. Compliance with Regulations:

Healthcare facilities must adhere to stringent regulations and standards. Pure steam helps these facilities comply with regulatory requirements related to sterility and patient safety.

Check this blog Behind the Purity: Pure Steam Generators in Pharma Production, to learn more about the Compliance of Pure Steam Generators with regulatory standards.

3. Cost-Effective and Sustainable:

Pure steam is more cost-effective and sustainable than other sterilisation methods. It eliminates the need for chemical sterilants, reducing environmental impact and operational costs over time.

4. Autoclave Efficiency:

Healthcare facilities commonly use pure steam in autoclaves to sterilise surgical instruments and medical supplies. The high temperature and purity levels contribute to effective sterilisation.

5. Pharmaceutical Production:

Pure steam is integral in pharmaceutical manufacturing, particularly during clean-in-place (CIP) and sterilize-in-place (SIP). It ensures the purity of pharmaceutical products by eliminating contaminants.

6. Reduced Residual Chemicals:

Unlike chemical sterilisation methods, pure steam sterilisation leaves no chemical residues on sterilised items. No residual chemicals are crucial in healthcare to prevent patient exposure to potentially harmful substances.

7. Safe for Sensitive Equipment:

The absence of chemicals in pure steam makes it safe for use with sensitive medical equipment and devices, preventing damage or contamination that could occur with other sterilisation methods.

8. Environmental Considerations:

Pure steam sterilisation contributes to environmental sustainability by eliminating the need for chemical sterilants. It aligns with healthcare’s commitment to eco-friendly practices.

Conclusion

In healthcare settings, relying on pure steam for sterilisation processes is a testament to its efficacy and importance in ensuring patient safety and maintaining aseptic conditions. Integrating pure steam systems in critical environments will remain a cornerstone in the ongoing commitment to healthcare sterility standards as technology advances. Healthcare facilities can uphold the highest quality, safety, and patient care levels by prioritising pure steam.

FAQs

1. What are pure steam specifications?

Pure steam is produced when water is heated above 100℃ and vaporised. It has no added substance and is free from any impurities.

2. How is steam used in Healthcare?

Steam is used for various purposes like Sterilisation, CIP& SIP, chronic wound recovery, Surgical Operations, and humidified controlled environments.

3. How is pure steam used in pharmaceutical manufacturing?

Pure steam is used in pharmaceutical manufacturing processes for equipment sanitisation and component sterilisation.

4. What is steam used for in hospitals?

Pure steam at high temperatures and pressure kills microorganisms on the stainless steel utensils and autoclaves to sterilise gowns and gauzes. Pure steam is also used to humidify air in operation rooms and patient wards to avoid any exposure to pathogens.